English

English

Using advanced technology and craftsmanship to create Wolong quality

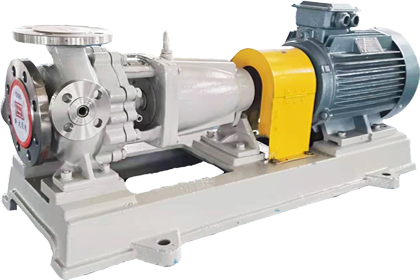

In terms of centrifugal pumps, we use mechanical seals, and their biggest features are affordability and durability. In terms of magnetic pumps, we use a spacer seal to completely isolate the medium from the transmission device.

The material used is fluoroplastic or stainless steel, which can be used for most strong acids, strong alkalis, and various corrosive media.

The configuration allows for universal replacement of corresponding accessories, making the product suitable for most working conditions

The product has low noise, no need to add lubricating oil for diameters below DN125, and no oil pollution.

The product shell is made of cast iron or stainless steel and coated with anti-corrosion paint to make the product durable.

We have a design team of up to 50 people, with a minimum bachelor's degree, and a professional mold development workshop.

Wolong Pump & Valve sincerely invites you to witness the quality and win the future together

Anhui Wolong Pump and Valve Co., Ltd., as a source factory specializing in chemical pump manufacturing, always takes deep industry accumulation as its core, and provides highly matched exclusive fluid solutions for the demanding needs of different chemical scenarios. From the transportation of corro...

View MoreForty years of trials and tribulations, forty years of spring blossoms and autumn fruits. October 5th, 2025, a day destined to be remembered by all Wolong people. The factory area of Anhui Wolong Pump and Valve Co., Ltd. is filled with a festive and enthusiastic atmosphere. We are excited and proud...

In order to implement the core concept of "people-oriented, caring for employees" in the enterprise, ANHUI WOLONG PUMP&VALVE CO.LTD has always paid attention to the well-being of employees' families and specially set up a "college entrance examination bonus for employees' children" to help...

The flag of the August 1st Army is red, and loyalty is forged with passion! On the occasion of the 98th anniversary of the founding of the Chinese People's Liberation Army, Anhui Wolong Pump and Valve Co., Ltd. extends high respect and sincere greetings to all soldiers and veterans! Thank you for gu...

QB magnetic pump has a compact structure, beautiful appearance, small volume, low noise, reliable operation, and easy maintenance. The product is widely used in chemical, acid and alkali production, smelting, rare earth, pesticide, dye, pharmaceutical, papermaking, electroplating, acid washing, radio, scientific research institutions, national defense industry and other units to pump acid, alkali, rare and valuable liquids such as oil, venom, volatile liquids, especially for the pumping of easily leaked, flammable and explosive liquids. Choosing a matching explosion-proof motor is more ideal. COB magnetic pump replaces dynamic seal with static seal, keeping the pump chamber in a completely sealed state, eliminating shaft seal and indirectly driving through magnetic coupling, completely eliminating the trouble of leakage and never polluting the use site. Due to the use of "gas plastic alloy" for the overcurrent part of the pump. It can continuously transport corrosive media such as acids, alkalis, and strong oxidants of any concentration without damage. IMD type magnetic pump is a newly developed high-power and high head magnetic drive pump. The pump's appearance and installation dimensions are designed and manufactured according to the S0 international standard. The motor is directly connected and supported by a middle bracket, with a compact structure and easy disassembly. The performance range is O=6-130m3/h H=17-50m. The pump uses high-performance magnetic material "neodymium iron boron" as the inner and outer magnets, and the isolation sleeve uses imported non-metallic materials, greatly reducing magnetic eddy current loss. It can transport high concentration and strong corrosive media with a density greater than 1.84/m3. The main components use steel lining F46. The pump body has high strength and can withstand corrosion from all strong acids and alkalis. It adopts a magnetic drive structure to prevent dripping and never pollute the use site. It is particularly suitable for transporting flammable and highly corrosive media. Explosive, toxic, volatile, and valuable media have replaced imported magnetic pumps in many projects. When the flow rate is low and the head is high, IMD type magnetic pumps should be selected.

(1) Check for any looseness in the magnetic pump pipeline and joints. Rotate the magnetic pump by hand to see if it is flexible

(2) Add bearing lubricating oil into the bearing body, and observe that the oil level is at the centerline of the oil gauge. The lubricating oil should be replaced or replenished in a timely manner.

(3) Unscrew the water inlet plug of the magnetic pump body and inject water (or slurry).

(4) Close the gate valve, outlet pressure gauge, and inlet vacuum gauge of the water outlet pipeline,

(5) Tap the motor and try to see if the motor direction is correct.

(6) Start the motor, when the magnetic pump is running normally, open the outlet pressure gauge and the inlet vacuum pump to see if they display the appropriate pressure, gradually open the gate valve, and check the motor load at the same time. (7) Try to control the flow rate and head of the magnetic pump within the range indicated on the label as much as possible to ensure that the magnetic pump operates at the highest efficiency point, in order to achieve the maximum energy-saving effect. (8) During the operation of the magnetic pump, the bearing temperature should not exceed 35C of the ambient temperature, and the maximum temperature should not exceed 80C. If any abnormal sound is found in the magnetic pump, it should be stopped immediately to check the cause.

(10) When the magnetic pump needs to be stopped, first close the gate valve and pressure gauge, and then stop the motor

(11) Within the first month of operation, the magnetic pump needs to change the lubricating oil after 100 hours, and then every 500 hours thereafter.

(12) Regularly adjust the packing gland to ensure normal dripping inside the packing chamber (preferably in droplets).

(13) Regularly check the wear of the shaft sleeve, and replace it promptly if there is significant wear.

(14) When using a magnetic pump in the cold winter season, after parking, the drain plug at the bottom of the pump body should be unscrewed to drain the medium completely. Prevent frost cracking.

(15) If the magnetic pump is not used for a long time, it is necessary to disassemble the pump completely, dry off the water, apply grease to the rotating parts and joints, and store them properly.

The working principle of check valve: The working principle of check valve is to allow the medium to flow in only one direction and prevent the flow in that direction. Usually, this type of valve works automatically, and under the pressure of fluid flowing in one direction, the valve disc opens; When the fluid flows in the opposite direction, the pressure of the fluid and the self weight of the valve block act on the valve seat, thereby cutting off the flow. Check valves belong to this type of valve, which includes swing check valves and lift check valves. The swing check valve has a hinge mechanism and a door like valve seat that freely rests on the inclined valve seat surface. In order to ensure that the valve seat can always reach the appropriate position on the valve seat surface, the valve seat is designed in a hinge mechanism so that the valve disc has sufficient swing space and the valve seat is truly and fully in contact with the valve seat. The Fujian office can be made entirely of metal, or it can be embedded with leather, rubber, or synthetic cover on top of the metal, depending on the performance requirements. When the swing check valve is fully opened, the fluid pressure is almost unobstructed, so the pressure drop through the valve is relatively small. The valve seat of the lift check valve is located on the sealing surface of the valve seat on the dry valve body. This valve, except for the valve disc that can be raised and lowered from the center, is similar to a load stop valve in other parts. Fluid pressure lifts the valve disc from the sealing surface of the valve seat, causing the medium to reflux and causing the valve to fall back onto the valve seat, cutting off the flow. According to the usage conditions, the valve body can be made of all metal structure or embedded with rubber, rubber pads or rubber rings on the valve body frame. Like a globe valve, the passage of fluid through a lift check valve is also narrow, so the pressure drop through the lift check valve is greater than that through a swing check valve, and the flow of a swing check valve is less restricted. Common faults and troubleshooting methods of check valves include: valve breakage; ② Medium backflow. The reason for the breakage of the valve disc is that the pressure of the medium before and after the check valve is in a nearly balanced and mutually "sawing" state, and the valve often hits the valve seat, causing the valve disc made of some brittle materials (such as cast iron, brass, etc.) to be broken. The preventive measure is to use check valves with resilient valve discs. The reasons for quality backflow include: ① damage to the sealing surface; ② inclusion of impurities. Repairing the sealing surface and cleaning impurities can prevent backflow.

Cooperation with big pump and valve brands is more assured

39 years of R&D experience is stable and reliable

Professional technical support from beginning to end

7X24 hours gold medal service

Copyright @ 2026 Anhui Wolong pump&valve CO.,LTD All Rights Reserved.

Sitemap

/ Blog

/ Xml

/ Privacy Policy

Network Supported

Network Supported