English

English

Order(MOQ) :

1Product Origin :

CNColor :

Green or customSafety Notice

To avoid accident or damage, please be sure to read the Safety Notice carefully before use of the pump. Be sure to follow the safety instructions in this section. The Operating Instructions is very important and may prevent the pump operator or other people from injury or mitigate property damage.

1.Safety Warnings

1)Hazard of magnetic field: The pump driven by magnetic force will generate a very powerful magnetic field that will cause adverse impact to those who wear electronic medical devices (e.g. electronic pacemaker).

2)Be sure to cut off the power supply before repair or other work. When there is someone repairing the pump, take protective measures to prevent other operators from switching on the power supply by mistake. In noisy or dark environment, place a clear sign beside the power switch to warn others. Switching on the power supply by mistake during maintenance may cause severe accident or even human death. Every person shall take special care.

3)Please wear safety goggles, protective gloves, protective clothes and other necessary protective equipment when replacing the pipe system or removing or assembling the pump.

4)When lifting the pump, use chain or belt to pass through the lug or motor to keep the pump and motor on level position. Do not stand beneath the lifted pump.

5)To avoid leakage, be sure to perform routine inspection and maintenance of the pump when it is used for trans porting the following dangerous liquids. In the event of leakage, such dangerous liquids (or volatile gas) will cause human death, explosion or fire.

a)Inflammable or explosive liquids;

b)Corrosive or poisonous liquids;

c)Liquids harmful to human body.

2.Safety Cautions

1)The magnetic pump will generate powerful magnetic field. Take care to prevent the strong magnetic force from causing harm to human body (e.g. squeezing your fingers).

2)Avoid idle run: Idle run may heat impeller axle and destroy the mechanical seal due to dry friction, thus resulting in damage to the pump. It is also deemed idle run if the pump works with the inlet and outlet valve closed.

3)Avoid damage due to static charge: Static charges will be generated if the pump is used for transporting the liquids of low conductivity, e.g. ultra-pure water or fluorine-contained inert fluids. This will cause electric discharge and damage to the pump. Measures shall be taken to prevent the generation of static charges or other measures shall be taken to lead the static charges.

4)The pump maintenance personnel shall have professional knowledge and operating experiences.

5)Magnetic pump made of special materials shall be used for designated working conditions only; otherwise there is no way to ensure the normal performance and service life of the pump, or it may even cause accident.

6)Requirements for site ventilation: If the pump is used for transporting the volatile poisonous gas, safety measures, e.g. ventilation equipment, must be taken to avoid liquid leakage in case of emergency.

7)Avoid liquid leakage: To prevent the liquid from flowing directly into the ground, protective measures shall be taken against the leakage caused by emergency accident or pipe damage.

8)Select the electromagnetic switch according to the motor specification, e.g. rated voltage and rated power.

9)If the pump is installed outdoor, protective measures must be taken for the electric circuits, thus to prevent the water from flowing into the switch.

10)The electromagnetic switch and buttons shall be installed safely and away from the pump.

Introduction

1.Use and Features

This pump is widely used in such industries as petrochemicals, acid / alkali making, non-ferrous smelting, acid wash in automobile manufacturing, rare earth separation, pesticides, dyes, pharmaceuticals, papermaking, electro-plating and radio. Features: With shaft seal removed, indirect drive by magnetic coupling has eliminated the troublesome dripping, causing no pollution to the site. As the overflow part of the pump is manufactured of fluorine plastic alloy, the pump may transport the acid, alkali, strong oxidants or other corrosive medium of any concentration continuously with no damage.

2.Unpacking and Inspection

Check the following after unpacking:

(1)If the product is what you have ordered.

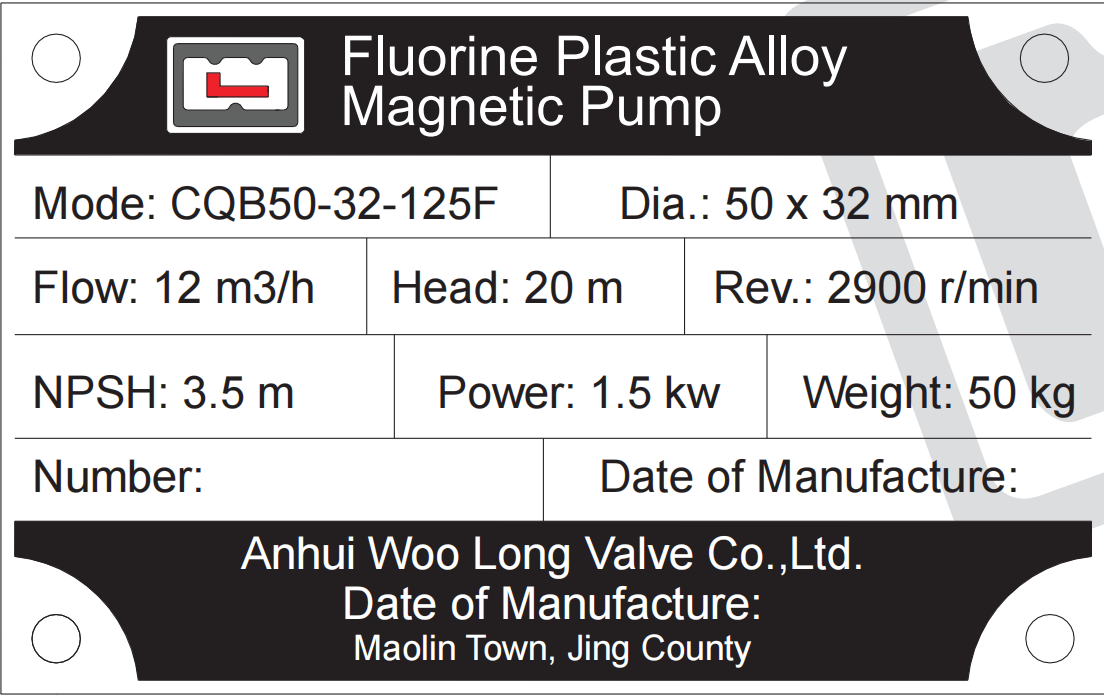

Check the data on the nameplate of the pump and motor to

ensure if they conform to your order requirements.

(2)If the pump is damaged during transport

and if the bolts are loose.

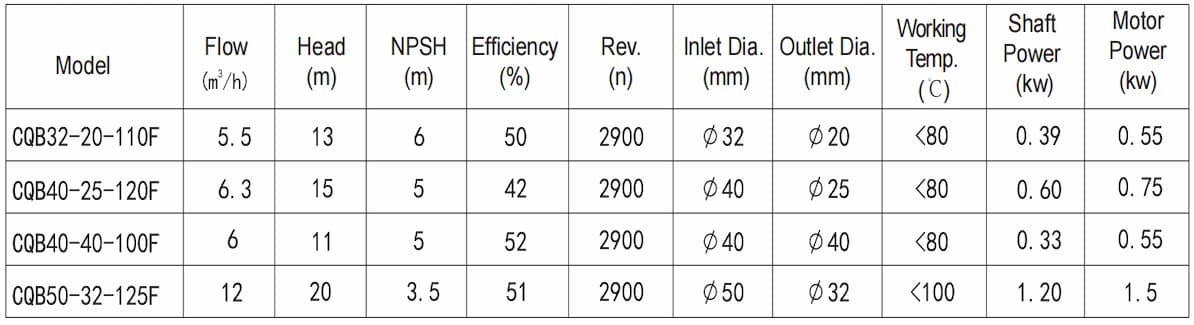

3.Model and Parameters

Notes:

1)Motor step: 2-step

2)If the specific gravity of the medium exceeds 1.3g/cm3, the user is suggested to add the power of compatible motor as appropriate.

3)If the medium contains HF acid or some special medium, it is needed to replace with special components according to the medium properties.

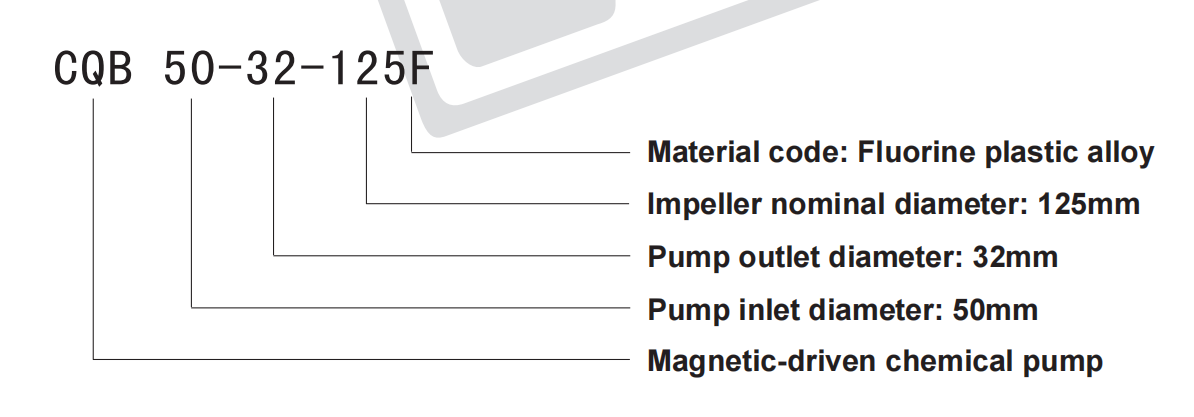

4.Model Definition

5.Scope of Application

1)Pressure limit: The pressure limit is 0.6MPa. Take care that the output pressure of the pump shall not exceed the pressure limit.

2)Impact of liquid temperature:

Range of working temperature: -20~100℃

Variance of ambient temperature: 0~40℃

Variance of ambient humidity: 35~85%RH

3)If the working temperature is within 100℃~150℃, the flow passage components shall be made of fluorine plastic resistant to high temperature.

4)Never use the magnetic pump for transporting the liquid that contains particles or crystals.

5)Impact of liquid viscosity to pump performance: The pump performance varies with the liquid viscosity.

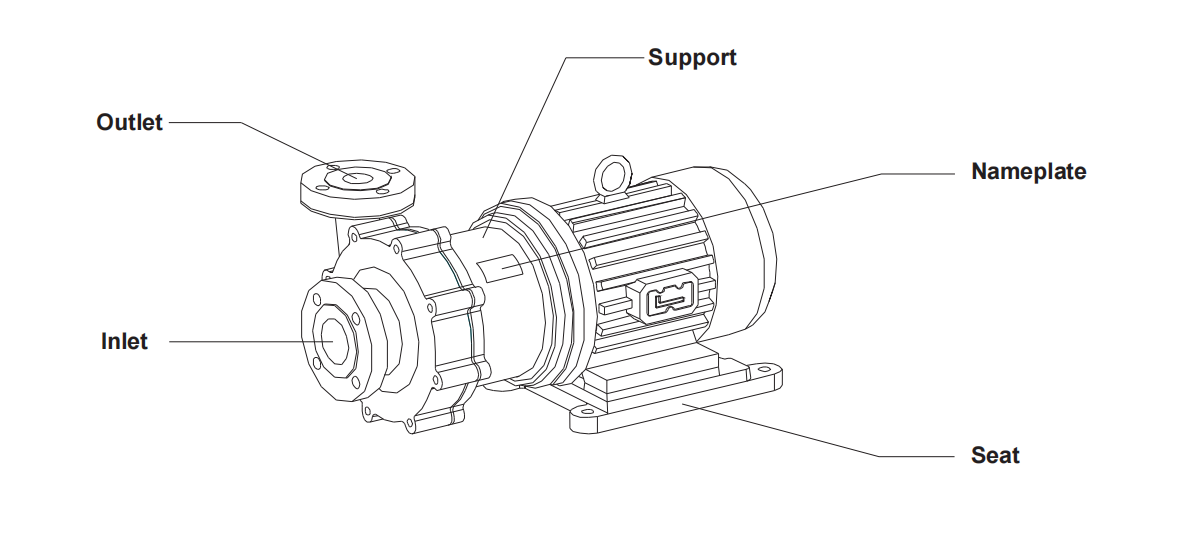

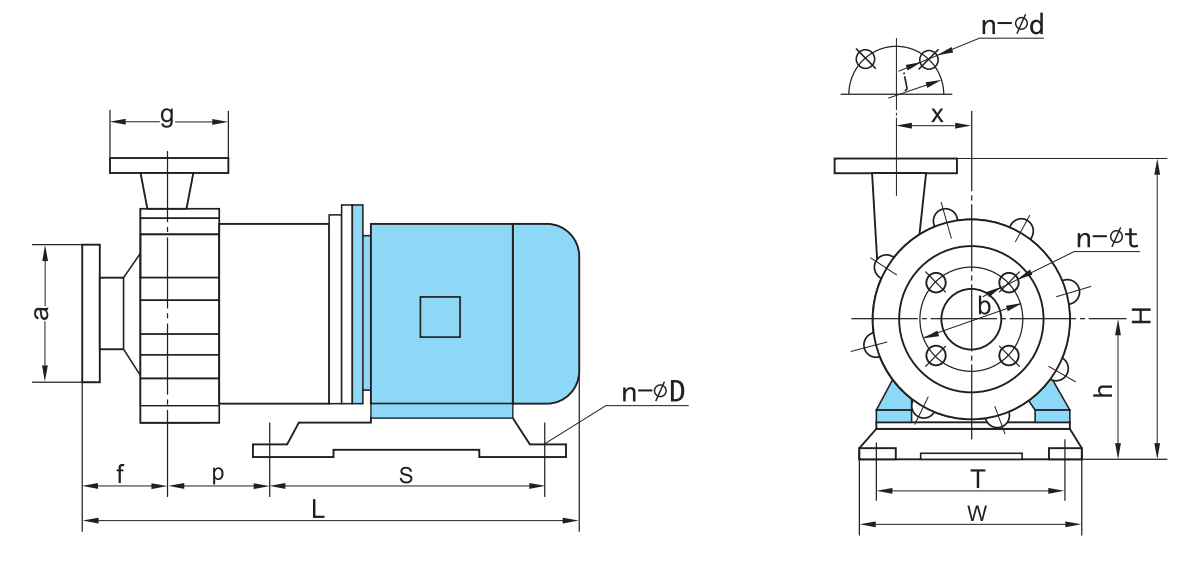

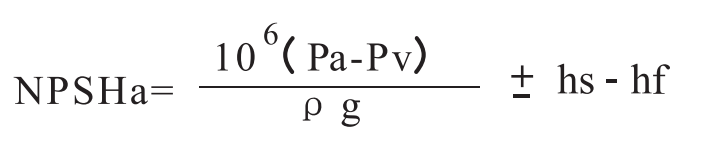

6.Structure and Parts Name

Installation:

1.Mounting position:

1)The pump shall be installed and fixed on solid foundation free from the impact of mechanical vibrations.

2)For easy repair and maintenance, adequate space shall be left around the pump.

3)The foundation shall be larger than the pump seat.

4)Place the pump unit on the foundation. Gaskets shall be paved between the seat and foundation.

2.Pipe

1)The pipes into and out of the pump shall be supported. Do not use the pump as the support. The pipe diameter shall be compatible to the pump inlet / outlet size.

2)To prevent the foreign particles from entering the pump, filter shall be installed at the inlet. The filtration area shall be 3-4 times larger than the section area of the pipe.

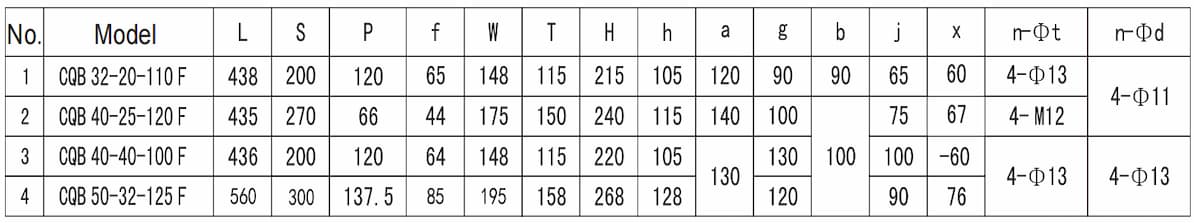

3)Ensure that the mounting height of the pump conforms to the NPSH. The pipe loss and medium temperature shall be also considered. To avoid NPSH within pump body, be sure to follow the formula

below:

Pa: Pressure applied onto the surface of transported medium (MPa)

Pv: Steam pressure of the medium (MPm)

g: Gravitational acceleration (m/s)

ρ: Medium density (kg/m3)

hs: Height of suction (m)

hf: Resistance of suction pipe (m)

4)Minimize the use of bent pipe and use the shortest pipe.

5)Do not use the protruded pipe or inverted U-pipe. The inlet pipe shall be connected upward per 1/100 gradient.

6)If the pump inlet diameter differs from outer diameter, please use eccentric reducing pipe and make the upper part level. If connected in reverse, it is possible that the gas inside the pipe cannot be discharged.

7)The pipe must be correctly connected. The sealing gasket between the flanges shall be smooth and not be mal-positioned. If there is leakage on the seal, the pump cannot work normally and the pump might be even damaged.

8)The resistance will increase greatly if the outlet pipe is too long. This will affect the overall perfor mance of the pump. Take this into consideration when selecting the pump.

9)To ensure accurate fulfillment of the flow requirements under working conditions, a gate valve shall be installed on the outlet pipe. To avoid surge when the pump is closed, a check valve shall also be installed. The correct sequence of installation shall be pump check valve gate valve.

Operation and Maintenance

1.Cautions before Use

1)Always prevent the magnetic pump from idle run. (It is also deemed idle run if the pump works with the gate valve closed).

2)Check the pump for its rotating direction. The pump will be damaged if the pump rotates in reverse direction.

3)If cavitations occur when the pump is running, be sure to stop the pump within one (1) minute.

4)It is suggested to keep the magnetic pump running continuously. Frequent start / stop will result in shortened life of the pump. If you have to use the pump intermittently, the start / stop within 1 hour shall not exceed 5 times.

5)The variance of medium temperature shall be controlled within 40℃. If the temperature rise / drop are too high, it might cause damage to the pump components (e.g. shaft, bearing).

6)If there is sudden power failure when the pump is running, be sure to cut off the power supply immediately and close the outlet valve.

7)The minimum flow of the pump during operation shall be ≥35% of the design value.

8)Pump noise: ≤85dB

2.Start and Operation

1)Before start, fill the pump with the liquid to be transported. Then, close the outlet valve and connect the power correctly.

2)Switch on the power and check if the pump rotates in correct direction.

3)Test run the pump for 5 – 10 minutes. If there is no abnormality, put the pump into normal operation.

4)To stop the pump, firstly close the outlet valve and then disconnect the power supply.

3.Repair and Maintenance

1)Check the pump and motor regularly. Replace the easily-damageable components.

2)If the pump is stopped and placed long out of service, the flow passage inside the pump shall be flushed and the power supply shall be disconnected.

3)Always avoid idle run.

4.Service Commitment

1)Long-term supply is ensured for the easily-damageable parts and other components.

2)New model of corrosion-resistant pump and explosion-proof motor may be designed according to the user requirements.

3)We provide technical supports and life-long services for our products.

4)We provide door-to-door commissioning and repair free of charge (The easily-damageable parts are charged per the ex-works price).

5.Explosive View

|

Fault

|

Cause

|

Solution

|

|

No liquid pumped

|

1. There is air in the suction pipe.

2. The suction pipe leaks air.

3.The liquid filled into the pump is insufficient. 4.The suction pipe is blocked by foreign substances.

5. The pump rotates in wrong direction.

6. The suction height is too high.

|

1. Refill liquid or exhaust the air.

2. Check the suction pipe.

3.Refill liquid.

4.Clear off the foreign substances.

5. Adjust the rotating direction of the pump.

6. Reduce the mounting height of the pump.

|

|

The flow is low

|

1. Impeller is damaged.

2. The rotating speed is low.

3. The pipe is blocked by foreign substances.

|

1. Replace the impeller.

2. Check the motor and electric circuit.

3. Clear off the foreign substances.

|

|

The power is too high

|

1. The specific gravity of the medium is too high.

2. Error between pump axis and motor axis is too high.

3. Mechanical friction exists.

|

1. Replace with the motor or pump that has a higher power.

2. Readjust.

3. Check the position of friction and make repair.

|

|

Pump head is low

|

1. There is air in the medium transported.

2. Impeller is damaged.

3. The rotating speed is low.

4. The viscosity of transported medium is too high.

|

1. Refill liquids or exhaust the air.

2. Replace the impeller.

3. Check the motor and electric circuit.

4. Reduce the viscosity or add the filling pressure.

|

|

The pump has vibration

|

1. Error between pump axis and motor axis is too high.

2. The suction height is too high, thus generating cavitations.

3. Mechanical friction exists.

|

1. Readjust.

2. Reduce the mounting height or replace with self-suction pump.

3. Check the position of friction and make repair.

|

|

Model

|

Power

|

Gross Weight

|

Model

|

Power

|

Gross Weight

|

|

CQB32-20-110F

|

0.55kw

|

18kg

|

CQB40-40-100F

|

0.55kw

|

20kg

|

|

CQB40-25-120F

|

0.75kw

|

35kg

|

CQB50-32-125F

|

1.5kw

|

45kg

|

Copyright @ 2025 Anhui Wolong pump&valve CO.,LTD All Rights Reserved.

Sitemap

/ Blog

/ Xml

/ Privacy Policy

Network Supported

Network Supported