CQB series of fluorine plastic alloy magnetic pump

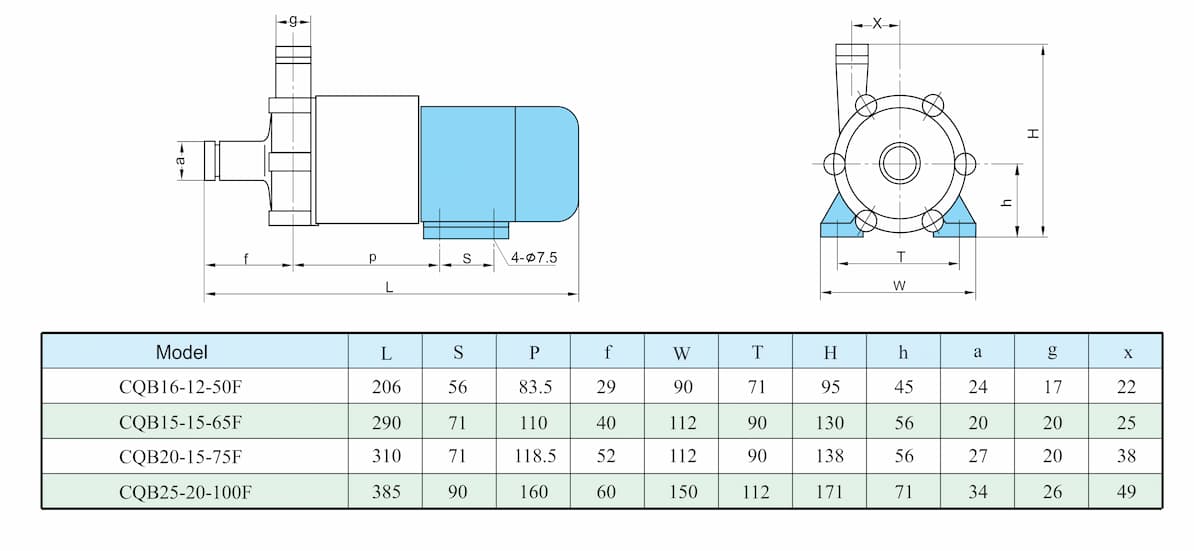

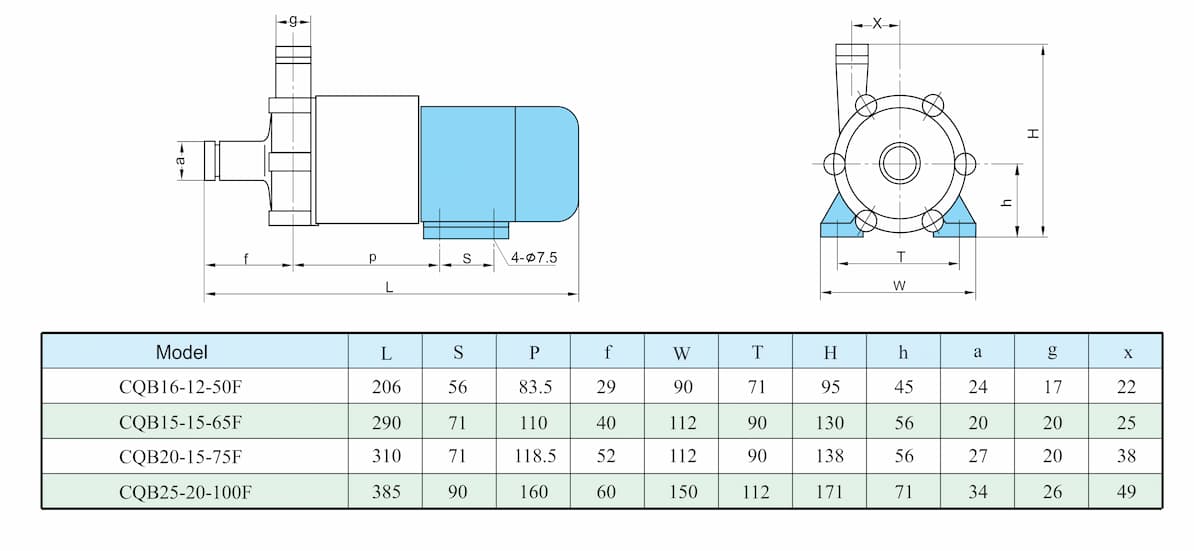

Model and Parameters

Notes:

1)Motor step: 2-step

2)If the specific gravity of the liquid exceeds 1.3g/cm3, the user is suggested to add the power of compatible motor as appropriate.

3)If the liquid contains HF acid or some special medium, it is needed to replace with special components according to the liquid properties.

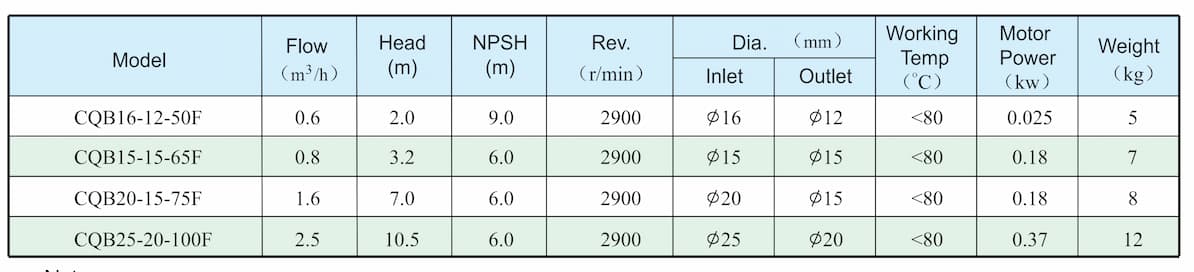

1)Pressure limit: The pressure limit is 0.6MPa. Take care that the output pressure of the pump shall not exceed the pressure limit.

2)Impact of liquid temperature:

Range of working temperature: -20~100℃

Variance of ambient temperature: 0~40℃

Variance of ambient humidity: 35~85%RH

3)Never use the magnetic pump for transporting the liquid that contains particles or crystals.

4)Impact of liquid viscosity to pump performance: The pump performance varies with the liquid viscosity.

Mounting Size

Operation and Maintenance Operation and Maintenance

Installation and Cautions

1.Prepare the concrete foundations according to the size requirements, and embed the anchor bolts properly.

2.Before installation, check the pump and motor carefully for any damage or foreign substances inside.

3.Place the pump on the foundation. Place wedge pads in pairs between the seat and foundation. Then, level the pump by

adjusting the wedge pads. After adjustment, tighten the anchor bolts.

4.The inlet and outlet pipe of the pump shall be otherwise supported.

5.After installation, use your hand to rotate the magnetic coupler to check if there is knock or end play. The rotation shall be easy and free.

6.Never use the magnetic pump for pumping the liquid that contains particles.

7.To prevent the foreign particles from entering the pump, filter shall be installed at the inlet. The filtration area shall be 3-4

times larger than the section area of the pipe.

8.For the pump with higher head, a check valve shall be installed on outlet pipe to avoid damage by surge when the pump is

suddenly stopped.

9.Ensure that the mounting height of the pump conforms to the NPSH. The pipe loss and liquid temperature shall be also

considered.

Start and Operation

To avoid damage to the impeller or other components, never control the flow by closing or adjusting the inlet valve.

1.Before start, fill the pump with the liquid to be transported (in case the pump is of upward suction). Close the outlet gate

valve and connect the power supply correctly.

2.Switch on the power and check if the pump rotates in correct direction.

3.Test run the pump for 5 – 10 minutes. If there is no abnormality, put the pump into normal operation.

4.To stop the pump, firstly close the outlet valve and then disconnect the power supply.

Repair and Maintenance

1.Check the pump and motor regularly. Replace the easily-damageable components.

2.If the pump is stopped and placed long out of service, the flow passage inside the pump shall be flushed and the power

supply shall be disconnected. Cover the pump with a dust cover.

Removal and Assembly

1.Firstly, flush the pump body with clear water until the corrosive liquid inside is thoroughly removed.

2.When replacing the components, never use the sharp or heavy objects to knock the pump parts. Please knock slightly with

a wood end wrapped with cloth. Handle the parts with care, with the sealing face placed upward.

3.The repair tools and metallic parts shall be kept away from the impeller and magnetic coupler.

Service Commitment

1)Long-term supply is ensured for the easily-damageable parts and other components.

2)New model of corrosion-resistant pump and explosion-proof motor may be designed according to the user requirements.

3)We provide technical supports and life-long services for our products.

4)We provide door-to-door commissioning and repair free of charge (The easily-damageable parts are charged per the

ex-works price).

Troubleshooting

| Fault |

Cause |

Solution |

| No liquid pumped |

1. There is air in the suction pipe.

2. The suction pipe leaks air.

3.The liquid filled into the pump is insufficient.

4.The suction pipe is blocked by foreign substances.

5. The pump rotates in wrong direction.

6. The suction height is too high.

|

1. Refill liquid or exhaust the air.

2. Check the suction pipe.

3.Refill liquid.

4.Clear off the foreign substances.

5. Adjust the rotating direction of the pump.

6. Reduce the mounting height of the pump.

|

| The flow is low |

1. Impeller is damaged.

2. The rotating speed is low.

3. The pipe is blocked by foreign substances.

|

1. Replace the impeller.

2. Check the motor and electric circuit.

3. Clear off the foreign substances.

|

| The power is too high |

1. The specific gravity of the medium is too high.

2. Mechanical friction exists.

|

1. Replace with the motor or pump that has a higher power.

2. Check the position of friction and make repair.

|

| Pump head is low |

1. There is air in the medium transported.

2. Impeller is damaged.

3. The rotating speed is low.

4. The viscosity of transported medium is too high.

|

1. Refill liquids or exhaust the air.

2. Replace the impeller.

3. Check the motor and electric circuit.

4. Reduce the viscosity or add the filling pressure.

|

| The pump has vibration |

1. The suction height is too high, thus generating cavitations.

2. Mechanical friction exists.

|

1. Reduce the mounting height or replace with self-suction pump.

2. Check the position of friction and make repair.

|

IH Series Stainless Steel Centrifugal Pump QBF Series Pneumatic Diaphragm Pump

CQ Series Stainless Steel Magnetic Pump FSB Series Fluorine Plastic Alloy Centrifugal Pump

IMD Series Fluorine Plastic Alloy Magnetic Pump FSB (D) Series Fluorine Plastic Alloy Centrifugal Pump

ZMD Series Self-suction Magnetic Pump FZB Series Fluorine Plastic Alloy Self-suction Pump

IHF Series Fluorine Plastic Alloy Centrifugal Pump FYH Series Fluorine Plastic Alloy Submerged Pump

IHF (D) Series Fluorine Plastic Alloy Centrifugal Pump Fluorine interlined valves, sight glass, pipes and fittings

UHB-ZK Series Mortar Pump MFY-I Series Wear and Corrosion Resistant Pump

GF Series Fluorine Interlined Pipe Pump

English

English

Network Supported

Network Supported