English

English

Item No :

111Order(MOQ) :

222Payment :

333Product Origin :

444Color :

555Safety Notice

To avoid accident or damage, please be sure to read the Safety Notice carefully before use of the pump. Be sure to follow the safety instructions in this section. The Operating Instructions is very important and may prevent the pump operator or other people from injury or mitigate property damage.

1.Safety Warnings

1)Hazard of magnetic field: The pump driven by magnetic force will generate a very powerful magnetic field that will cause adverse impact to those who wear electronic medical devices (e.g. electronic pacemaker).

2)Be sure to cut off the power supply before repair or other work. When there is someone repairing the pump, take protective measures to prevent other operators from switching on the power supply by mistake. In noisy or dark environment, place a clear sign beside the power switch to warn others. Switching on the power supply by mistake during maintenance may cause severe accident or even human death. Every person shall take special care.

3)Please wear safety goggles, protective gloves, protective clothes and other necessary protective equipment when replacing the pipe system or removing or assembling the pump.

4)When lifting the pump, use chain or belt to pass through the lug or motor to keep the pump and motor on level position. Do not stand beneath the lifted pump.

5)To avoid leakage, be sure to perform routine inspection and maintenance of the pump when it is used for trans porting the following dangerous liquids. In the event of leakage, such dangerous liquids (or volatile gas) will cause human death, explosion or fire.

a)Inflammable or explosive liquids;

b)Corrosive or poisonous liquids;

c)Liquids harmful to human body.

2.Safety Cautions

1)The magnetic pump will generate powerful magnetic field. Take care to prevent the strong magnetic force from causing harm to human body (e.g. squeezing your fingers).

2)Avoid idle run: Idle run may heat impeller axle and destroy the mechanical seal due to dry friction, thus resulting in damage to the pump. It is also deemed idle run if the pump works with the inlet and outlet valve closed.

3)Avoid damage due to static charge: Static charges will be generated if the pump is used for transporting the liquids of low conductivity, e.g. ultra-pure water or fluorine-contained inert fluids. This will cause electric discharge and damage to the pump. Measures shall be taken to prevent the generation of static charges or other measures shall be taken to lead the static charges.

4)The pump maintenance personnel shall have professional knowledge and operating experiences.

5)Magnetic pump made of special materials shall be used for designated working conditions only; otherwise there is no way to ensure the normal performance and service life of the pump, or it may even cause accident.

6)Requirements for site ventilation: If the pump is used for transporting the volatile poisonous gas, safety measures, e.g. ventilation equipment, must be taken to avoid liquid leakage in case of emergency.

7)Avoid liquid leakage: To prevent the liquid from flowing directly into the ground, protective measures shall be taken against the leakage caused by emergency accident or pipe damage.

8)Select the electromagnetic switch according to the motor specification, e.g. rated voltage and rated power.

9)If the pump is installed outdoor, protective measures must be taken for the electric circuits, thus to prevent the water from flowing into the switch.

10)The electromagnetic switch and buttons shall be installed safely and away from the pump.

Introduction

1.Use and Features

Installation:

1.Key Points of Installation:

2.Pipe

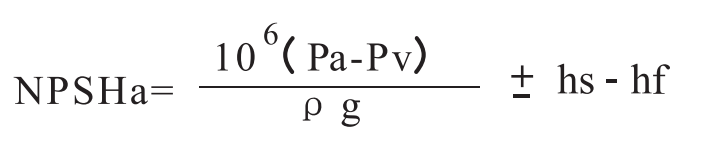

Pa: Pressure applied onto the surface of transported medium (MPa)

Pv: Steam pressure of the medium (MPm)

g: Gravitational acceleration (m/s)

ρ: Medium density (kg/m3)

hs: Height of suction (m)

hf: Resistance of suction pipe (m)

Operation and Maintenance

1.Cautions before Use

2.Start and Operation

3.Repair and Maintenance

4.Removal and Assembly

|

Fault

|

Cause

|

Solution

|

|

No liquid pumped

|

1. There is air in the suction pipe or the inlet is blocked.

2. The suction height is too high.

3. The required lift is higher than the pump head.

4. The discharge pipe is too thin and the pipe loss is too

high.

5. The pump rotates in wrong direction.

|

1. Clean the pipeline.

2. Reduce the mounting height of the pump.

3. Replace with the pump that has a higher head.

4. Replace with an output pipe that has the same

diameter as the pump diameter.

5. Adjust the rotating direction of the pump.

|

|

The flow is low

|

1. Impeller is damaged.

2. The seal is damaged.

3. The number of rotation is inadequate.

4. The number of rotation is low.

5. Too many elbows on outlet pipe, resulting in that the

resistance is too high.

|

1. Replace the impeller.

2. Replace the seal.

3. Increase the number of rotation. .

4. Reinstall the pipe according to specifications.

5. Rearrange the pipes as optimal.

|

|

The power is too high

|

1. The specific gravity of the medium is too high.

2. Mechanical friction exists.

|

1. Replace with the motor or pump that has a higher power.

2. Check the position of friction and repair.

|

|

Pump head is low

|

1. There is air in the medium transported.

2. Impeller is damaged.

3. The number of rotation is inadequate.

4. The viscosity of transported medium is too high.

|

1. Refill liquids or exhaust the air.

2. Replace the impeller.

3. Check the motor and power line.

4. Reduce the viscosity or add the filling pressure.

|

|

The seal is in severe leakage

|

1. The material is improper or there is corrosion.

2. Severe wear on the surface.

3. The static and dynamic ring is not mated.

4. The static ring is broken.

5. The dynamic ring of mechanical seal retreats.

|

1. Replace with proper dynamic and static ring.

2. Replace the worn parts, adjust the spring pressure and reduce the friction.

3. Adjust the static ring and dynamic ring for proper mating.

4. Replace the static ring.

5. Loosen the screws fixing the dynamic ring, position and lock it again.

|

|

There is abnormal noise in the pump

and the pump has vibration

|

1. The pump shaft is not coaxial with motor.

2. The flow exceeds the range.

3. The tension bolt is loose or fallen.

4. The motor shaft is worn and the bearing is damaged.

|

1. Calibrate the pump axis.

2. Select proper pump.

3. Remount the tension bolt.

4. Clean or replace the bearing and pump shaft.

|

Copyright @ 2026 Anhui Wolong pump&valve CO.,LTD All Rights Reserved.

Sitemap

/ Blog

/ Xml

/ Privacy Policy

Network Supported

Network Supported