Safety Notice

To avoid accident or damage, please be sure to read the Safety Notice carefully before use of the pump. Be sure to follow the safety instructions in this section. The Operating Instructions is very important and may prevent the pump operator or other people from injury or mitigate property damage.

1.Safety Warnings

1)Hazard of magnetic field: The pump driven by magnetic force will generate a very powerful magnetic field that will cause adverse impact to those who wear electronic medical devices (e.g. electronic pacemaker).

2)Be sure to cut off the power supply before repair or other work. When there is someone repairing the pump, take protective measures to prevent other operators from switching on the power supply by mistake. In noisy or dark environment, place a clear sign beside the power switch to warn others. Switching on the power supply by mistake during maintenance may cause severe accident or even human death. Every person shall take special care.

3)Please wear safety goggles, protective gloves, protective clothes and other necessary protective equipment when replacing the pipe system or removing or assembling the pump.

4)When lifting the pump, use chain or belt to pass through the lug or motor to keep the pump and motor on level position. Do not stand beneath the lifted pump.

5)To avoid leakage, be sure to perform routine inspection and maintenance of the pump when it is used for trans porting the following dangerous liquids. In the event of leakage, such dangerous liquids (or volatile gas) will cause human death, explosion or fire.

a)Inflammable or explosive liquids;

b)Corrosive or poisonous liquids;

c)Liquids harmful to human body.

2.Safety Cautions

1)Avoid idle run: Idle run may heat impeller axle and destroy the mechanical seal due to dry friction, thus resulting in damage to the pump. (It is also deemed idle run if the pump works with the inlet and outlet valve closed).

2)Avoid damage due to static charge: Static charges will be generated if the pump is uses for transporting the liquids

of low conductivity, e.g. ultra-pure water or fluorine-contained inert fluids. This will cause electric discharge and damage to the pump.

Measures shall be taken to prevent the generation of static charges or other measures shall be taken to lead the static charges.

3)The pump maintenance personnel shall have professional knowledge and operating experiences.

4)The pump made of special materials shall be used for designated working conditions only; otherwise there is no way to ensure the normal performance and service life of the pump, or it may even cause accident.

5)Requirements for site ventilation: Safety measures must be taken if the pump is used for transporting the volatile poisonous gas. For example, ventilation equipment may be installed to avoid liquid leakage in case of emergency.

6)Avoid liquid leakage: To prevent the liquid from flowing directly into the ground, protective measures shall be taken against the leakage caused by emergency accident or pipe damage.

7)Select the electromagnetic switch according to the motor specification, e.g. rated voltage and rated power.

8)If the pump is installed outdoor, protective measures must be taken for the electric circuits, thus to prevent the water from flowing into the switch.

9)The electromagnetic switch and buttons shall be installed safely and away from the pump.

Introduction

1.Overview

The GF Fluorine Interlined Pipe Pump is elaborately designed based on general vertical pump by adopting China’s superior hydraulic model and the performance parameters of Model IHF centrifugal pump. It is highly resistant to corrosion and may replace 316L stainless steel and titanium alloy. Other features include high efficiency, energy saving, low noise and high reliability.

2.Packaging and Inspection

Check the following after unpacking:

1)If the pump and its accessories (including the other documents required by the user) are complete as on the Packing List.

2)If the data on the nameplate of the pump and motor are according to the order requirements.

3)If the pump is damaged during transport and if the bolts are loose.

3.Model Definition

40GF-32

40: Pump inlet and outlet nominal diameter 40mm

GF: Fluorine interlined

32: Pump head 32m

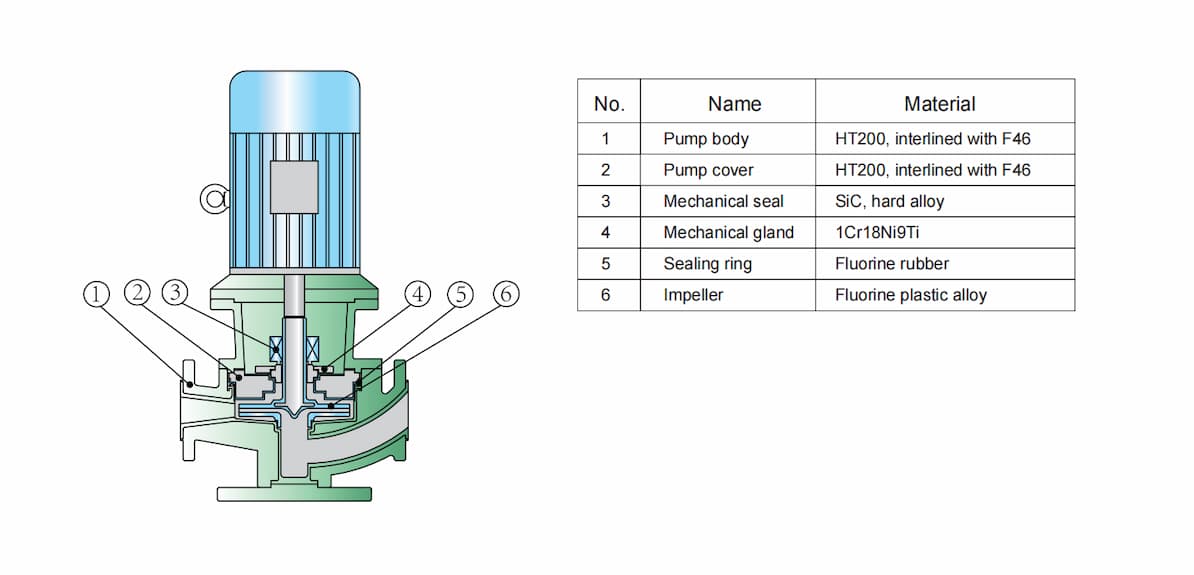

4.Structure and Parts Name

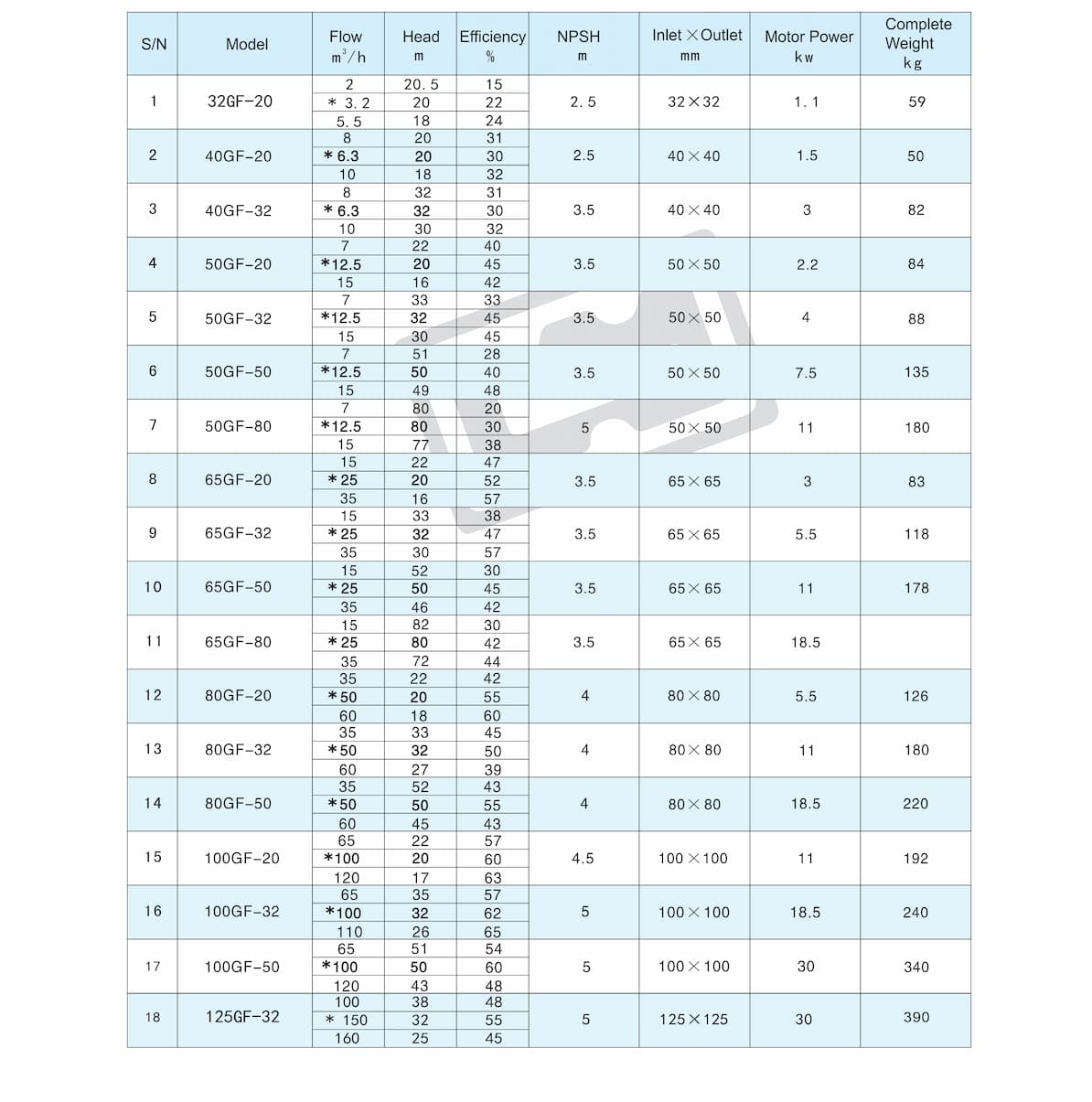

5.Model and Parameters

able 1: Installed with 2-step motor n=2900 r/min Design Pressure: 1.6MPa "*"refers to standard parameter.

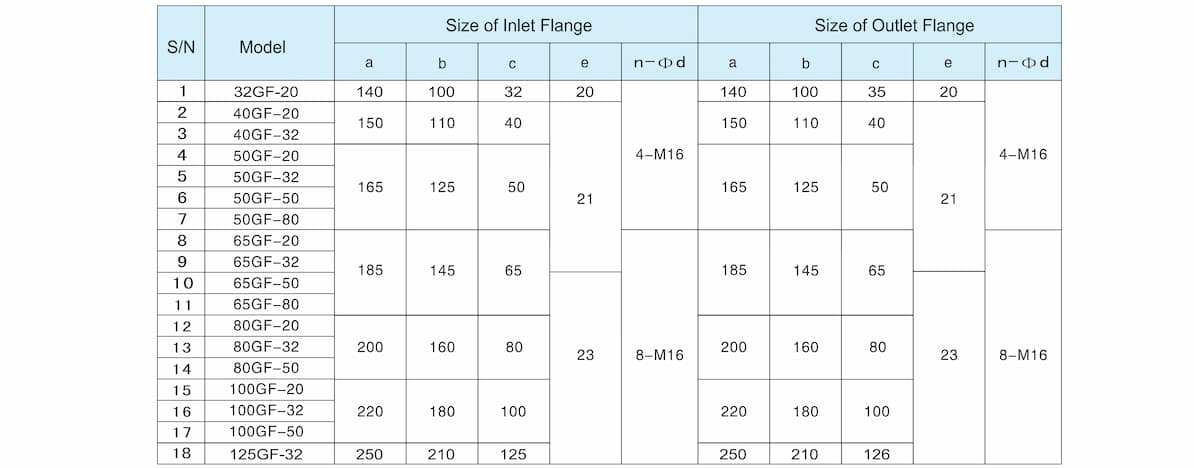

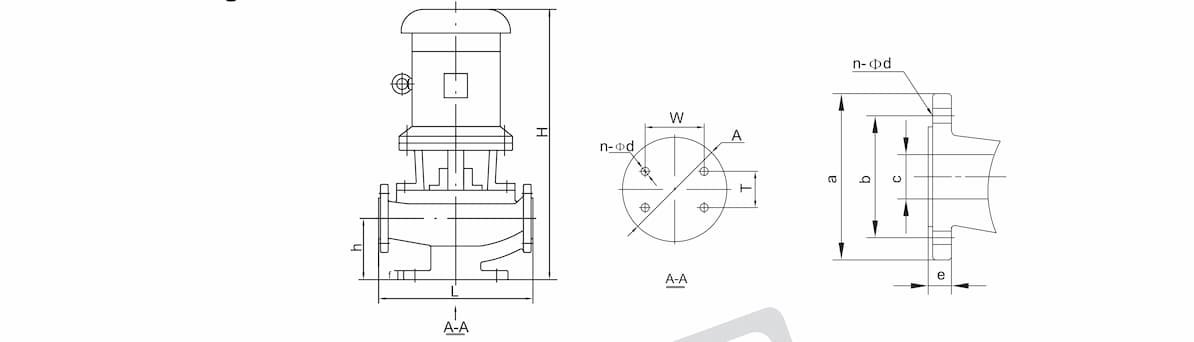

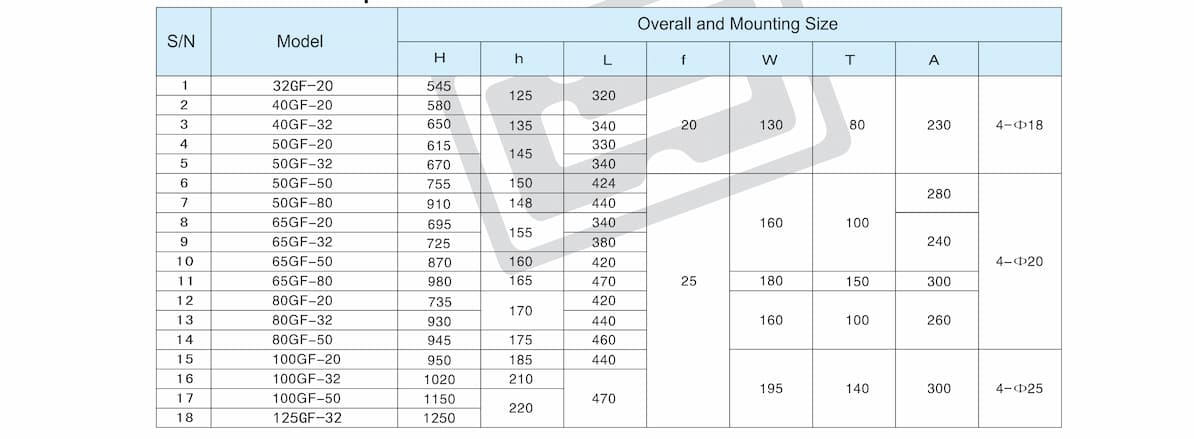

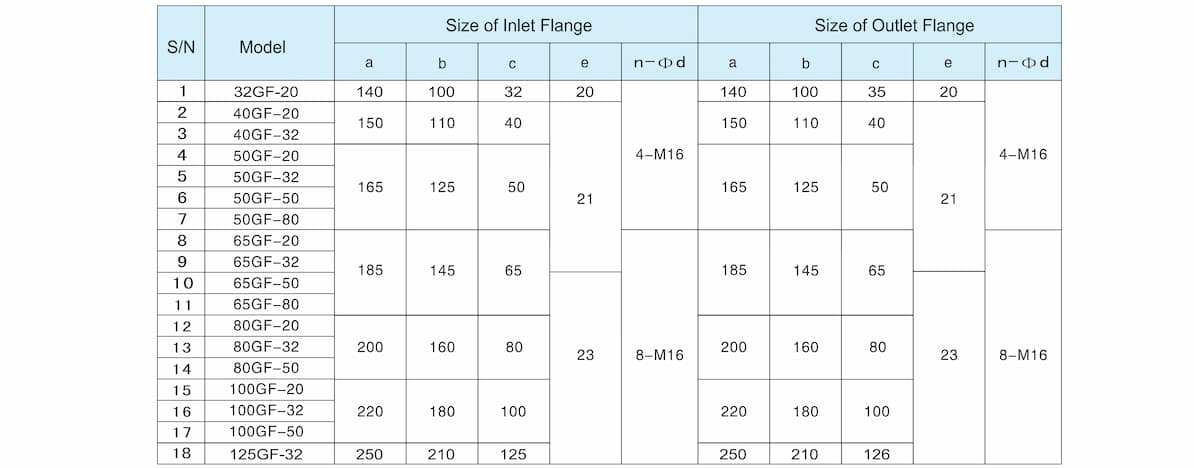

6.Mounting Size

Installed with 2-step motor 2900 r/min

Flange Standard No. HG/T20592-2009 Design Pressure: 1.6Mpa

7.Features and Scope of Application

1)The GF Fluorine Interlined Pipe Pump is of vertical structure. The inlet and outlet have the same diameter and on the same center line. With the motor mounted with rainproof housing, the pump may be placed outdoor.

2)The impeller of GF Fluorine Interlined Pipe Pump is directly mounted on motor shaft in an optimized manner to ensure effective balance of the radial and axial loads generated by the pump. This ensures the pump runs stably with low vibration and noise.

3)General and grain-resistant mechanical seal against abrasion and corrosion is adopted for the shaft of GF Fluorine Interlined Pipe Pump. The mechanical seal features in long service life.

4)The GF Fluorine Interlined Pipe Pump may be arranged in parallel or series according to the service requirements, i.e. the needs for flow and head.

5)GF Fluorine Interlined Pipe Pump is applicable to long-term transportation of acid, alkali, oxidants and other corrosive liquids in any concentration under -40~+150℃.

6)The inlet pressure of GF Fluorine Interlined Pipe Pump is ≤0.3MPa; the pump system pressure (i.e. pump inlet pressure + pump head) is ≤1.6MPa. Please note the system working pressure when placing the order.

7)The GF Fluorine Interlined Pipe Pump is widely used in such industries as petroleum, chemicals, metallurgy, electric power, papermaking, flue gas desulfurization, dust collection, food, pharmaceutical and synthetic fiber,

8.Installation Instructions

1)Before installation, check if the fasteners are loose and if the pump flow passage is blocked by foreign substances, thus to avoid damage to impeller and pump body during operation.

2)To avoid deforming the pump, the pipe weight shall not be added on the pump.

3)To avoid affecting the pump performance due to vibration at startup, the anchor bolts must be securely tightened.

4)For easy repair and safety, one regulating valve shall be installed on both the inlet pipe and outlet pipe of the pump, and one pressure gauge shall be installed close to the outlet, thus to ensure the pump runs normally within the rated flow and head. This helps to extend the service life of the pump.

5)After installation, move the pump shaft. The impeller shall have no friction or jam; otherwise, the pump shall be dismantled for finding the reason.

Operation and Maintenance:

1.Startup and Operation

Preparation before startup:

1)Test if the motor rotates in correct direction. Viewed from the top, the motor shall rotate in clockwise direction. To avoid dry abrasion of the mechanical seal, the test time shall be short.

2)Open the vent valve and have the entire pump body filled with liquids. Wait until the liquid is full and then close the vent valve.

3)Check if each part is normal.

4)Rotate the pump with your hand to make the lubricant enter into the end face of mechanical seal.

Startup:

1)Fully open the inlet valve;

2)Close the valve of outlet pipe;

3)Start the motor and check if the pump runs correctly;

4)Adjust the outlet valve to suit the working conditions. If the pump is installed with flow meter or pressure gauge at the outlet, the user shall adjust the outlet valve to make the pump run at the rated point as specified in the data sheet. If the pump is installed with flow meter or pressure gauge at the outlet, the user shall adjust the outlet valve and measure the motor current, making the motor run within the rated current; otherwise the pump may run under overload and the motor may be burnt.

5)Check the shaft seal for leakage. Normally, the leakage of mechanical seal shall be less than 3 drips per minute.

6)Check the motor and bearing for their temperature rise, which shall be ≤70℃.

Stop:

1)Close the valve of outlet pipe;

2)Stop the motor;

3)Close the inlet valve;

Thoroughly discharge the liquids if the pump is to be placed long out of use. Especially when the ambient temperature is lower than 0℃, please immediately discharge the liquids when the pump is stopped, so as to avoid damaging the parts due to freeze.

2.Repair and Maintenance

1)Check the pump and motor regularly. Replace the easily-damageable components.

2)If the pump is stopped and placed long out of service, the flow passage inside the pump shall be flushed and the power supply shall be disconnected. Always avoid idle run. If the pump is installed outdoor, rainproof measures shall be taken to prevent the motor from burn due to moisture.

3.Removal and Assembly

1)Close the inlet and outlet valve. Loosen the bolts fixing the motor to the pump body. Separate the motor and impeller from the pump body;

2)Remove the air housing at the rear part of the motor. Loosen the lock bolts at the tail of motor. Knock the nut and tension bolts with copper rod to separate the tail of impeller from the sleeve of motor shaft. Separate the impeller, pump cover, mechanical seal and support.

3)Loosen two (2) screws tightening the dynamic ring of mechanical seal. Then, remove the dynamic ring from the impeller shaft. Remove the pump cover; remove the screws fixing the gland of mechanical seal on the pump cover. Finally, remove the static ring of mechanical seal from pump cover.

4)If it is needed to remove the pump body, you have to remove the bolts connecting the inlet and outlet pipe, and the anchor bolts fixing the pump body.

4.Service Commitment

1)Long-term supply is ensured for the easily-damageable parts and other components.

2)New model of corrosion-resistant pump and explosion-proof motor may be designed according to the user requirements.

3)We provide technical supports and life-long services for our products.

4)We provide door-to-door commissioning and repair free of charge (The easily-damageable parts are charged per the ex-works price).

Statement: All the words, data and pictures in this text are for reference onlyand subject to updating without prior notification.

We will provide you the best services.

|

Fault

|

Cause

|

Solution

|

|

No liquid pumped

|

1. There is air in the suction pipe or the inlet is blocked.

2. The suction height is too high.

3. The required lift is higher than the pump head.

4. The discharge pipe is too thin and the pipe loss is too

high.

5. The pump rotates in wrong direction.

|

1. Clean the pipeline.

2. Reduce the mounting height of the pump.

3. Replace with the pump that has a higher head.

4. Replace with an output pipe that has the same

diameter as the pump diameter.

5. Adjust the rotating direction of the pump.

|

|

The flow is low

|

1. Impeller is damaged.

2. The seal is damaged.

3. The number of rotation is inadequate.

4. The number of rotation is low.

5. Too many elbows on outlet pipe, resulting in that the

resistance is too high.

|

1. Replace the impeller.

2. Replace the seal.

3. Increase the number of rotation. .

4. Reinstall the pipe according to specifications.

5. Rearrange the pipes as optimal.

|

|

The power is too high

|

1. The specific gravity of the medium is too high.

2. Mechanical friction exists.

|

1. Replace with the motor or pump that has a higher power.

2. Check the position of friction and repair.

|

|

Pump head is low

|

1. There is air in the medium transported.

2. Impeller is damaged.

3. The number of rotation is inadequate.

4. The viscosity of transported medium is too high.

|

1. Refill liquids or exhaust the air.

2. Replace the impeller.

3. Check the motor and power line.

4. Reduce the viscosity or add the filling pressure.

|

|

The seal leaks severely

|

1. The abrasive material is improperly

selected, and it is corroded.

2. The abrasive face is severely worn.

3. The dynamic and static ring does not match.

4. The static ring is broken.

5. The dynamic ring of mechanical seal moves backward.

|

1. Replace the dynamic and static ring.

2. Replace the worn parts and adjust the spring pressure to reduce the abrasion.

3. Adjust the dynamic and static ring to make

them match.

4. Replace the static ring.

5. Loosen the screws fixing the dynamic ring, and lock it to correct position.

|

There is abnormal noise in the pump

and the pump has vibration

|

1. The pump shaft is not coaxial with motor.

2. The flow exceeds the range.

3. The tension bolt is loose or fallen.

4. The motor shaft is worn and the bearing is damaged.

|

1. Calibrate the pump axis.

2. Select proper pump.

3. Remount the tension bolt.

4. Clean or replace the bearing and pump shaft.

|

CQB Series Fluorine Plastic Alloy Magnetic Pump FSB (D) Series Fluorine Plastic Alloy Centrifugal Pump

IMD Series Fluorine Plastic Alloy Magnetic Pump FYH Series Fluorine Plastic Submerged Pump

ZMD Series Self-suction Magnetic Pump MFY-I Series Wear and Corrosion Resistant Pump

UHB-ZK Series Mortar Pump IHF (D) Series Fluorine Plastic Alloy Centrifugal Pump

FZB Series Fluorine Plastic Alloy Self-suction Pump

Different fluorine interlined valves, sight glass, pipes and fittings

English

English

Network Supported

Network Supported