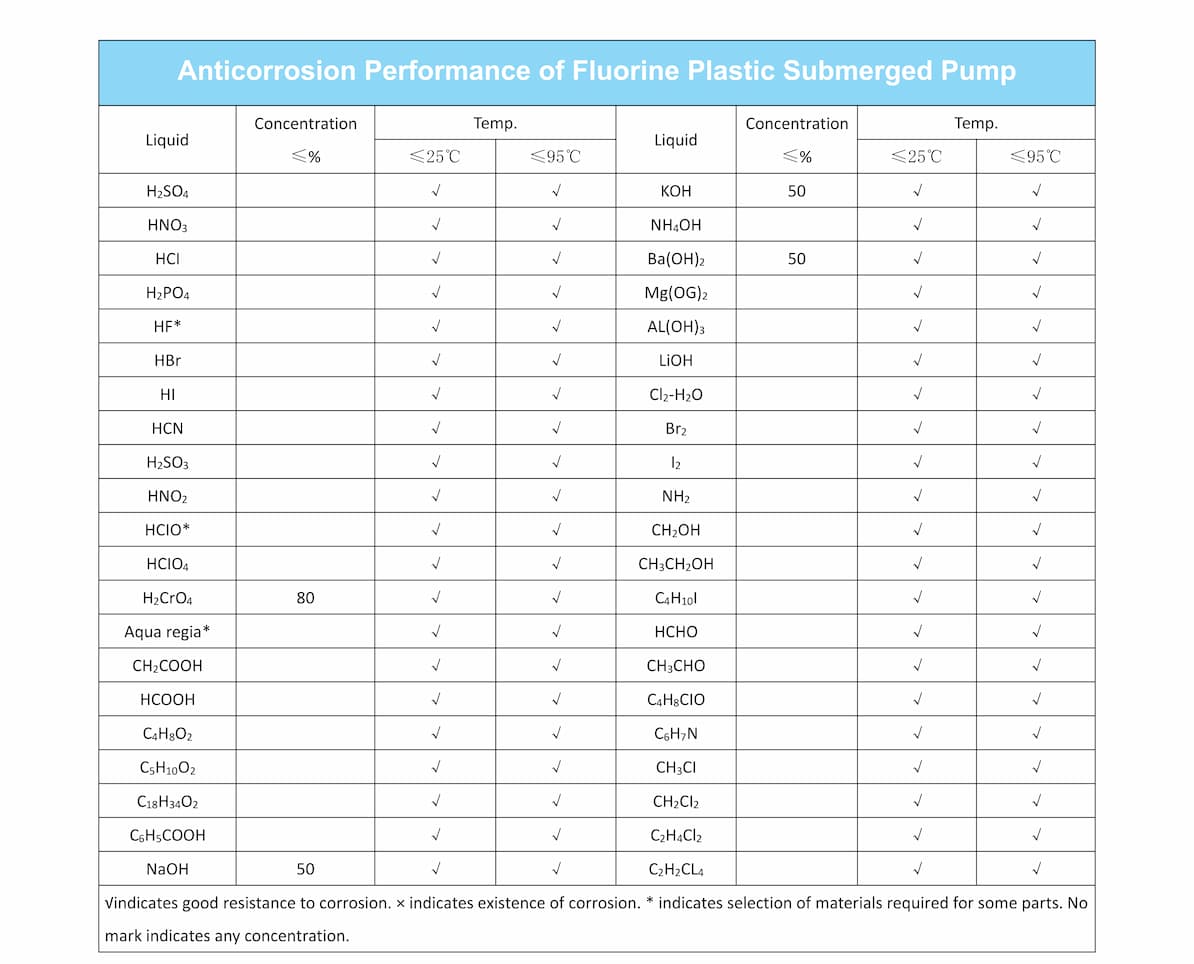

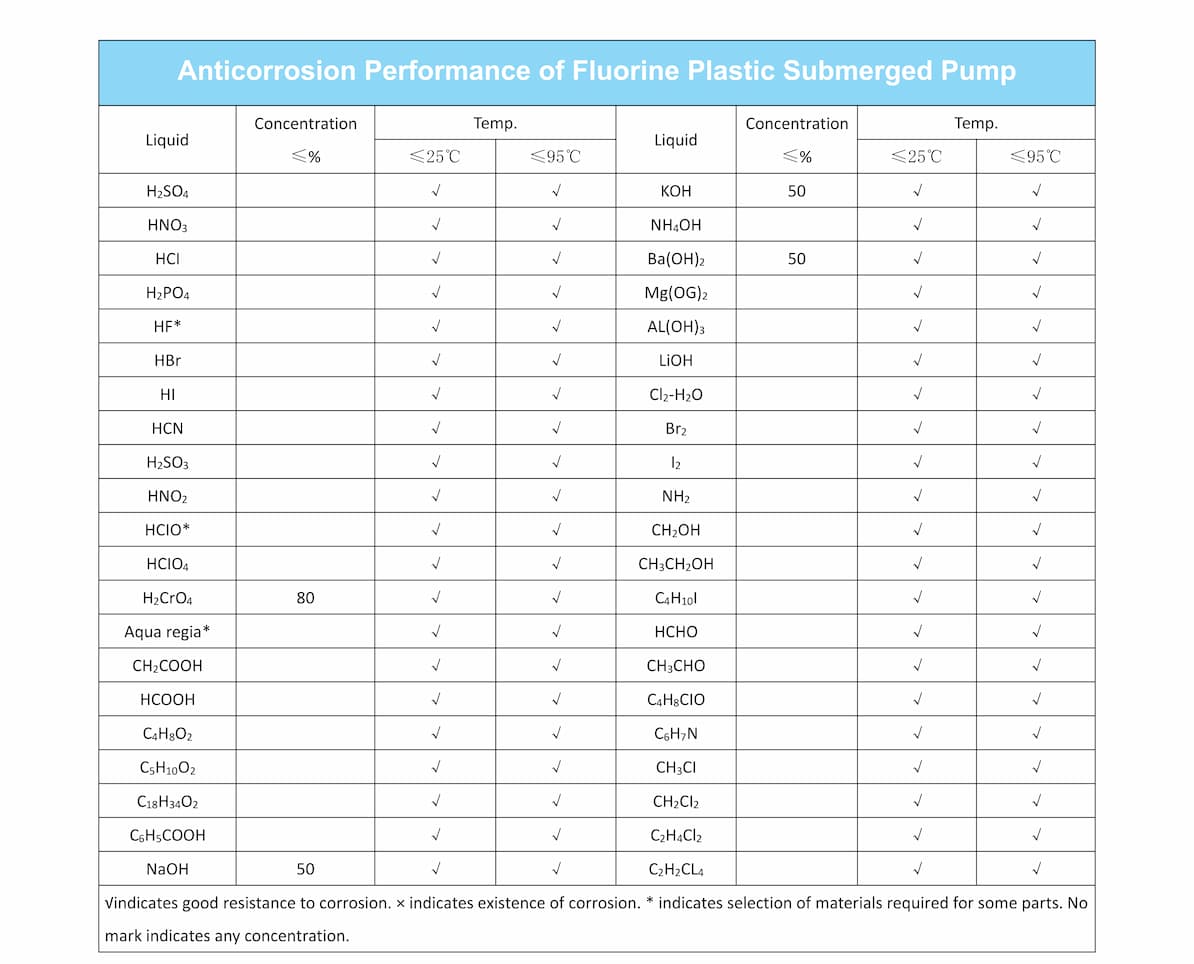

Use

This equipment is widely used for transporting the acid, alkali, organic solvent, strong oxidant and other corrosive liquids. Working temperature: -20~85℃.

Features

The Fluorine Plastic Vertical Sump Pump Model FYH is a long-shaft vertical centrifugal pump, and the parts in contact with the liquids are all made of fluorine plastic. It features in high efficiency, light weight, easy repair and wide range of anticorrosion. It can pump the medium without being filled with liquids.

Cautions for Installation and Operation

1.This pump is made of fluorine plastic. Be sure to handle it with care during transport, installation and removal.

2.To avoid damage to the support, shaft sleeve or fluorine plastic components, never pull, hang or lift the submerged portion of the pump shaft, the outlet pipe or those 3 pcs of rods connecting the support.

3.Before installation and use of the vertical sump pump, please firstly check each fastener for its tightness. Use your hand to rotate the pump shaft and check for no friction of hard object.

4.The pipe shall be supported otherwise. The pipe weight shall never be applied onto the pump.

5.The vertical sump pump must be vertically installed with no inclination.

6.To avoid vibration, the pump seat shall be tightly fixed to the storage tank and tank support.

7.The pump inlet filter shall be installed away from the vessel bottom for a distance at least 2 times the inlet diameter.

8.Start and operate the pump per the indicated direction. Be sure to avoid inverse rotation or idle run.

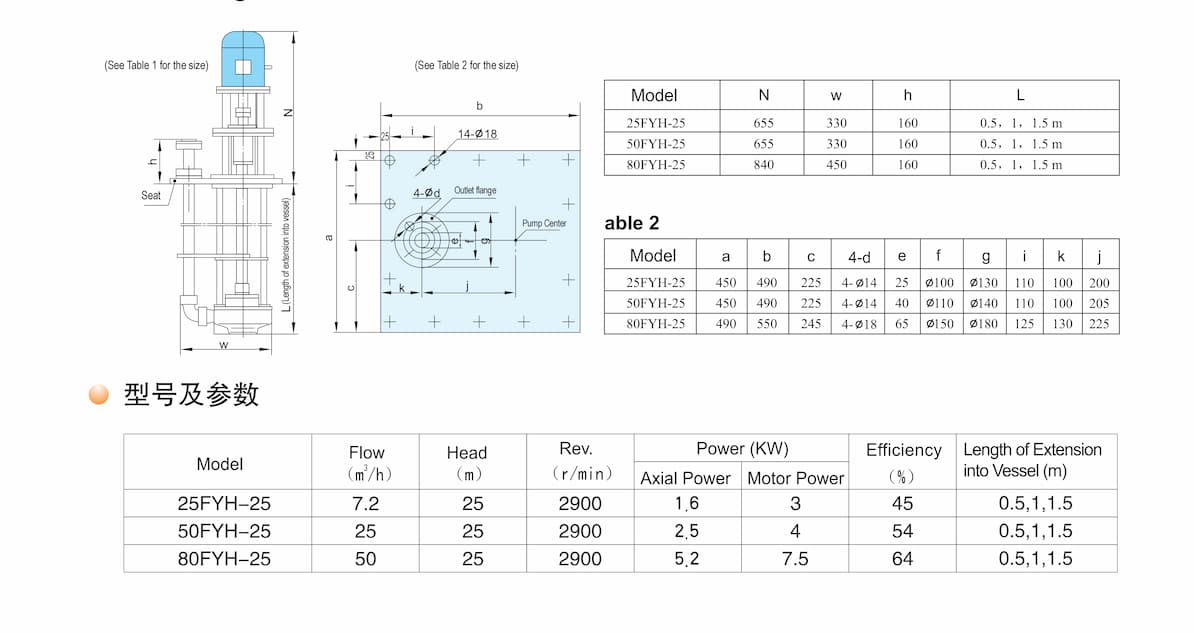

Mounting Size

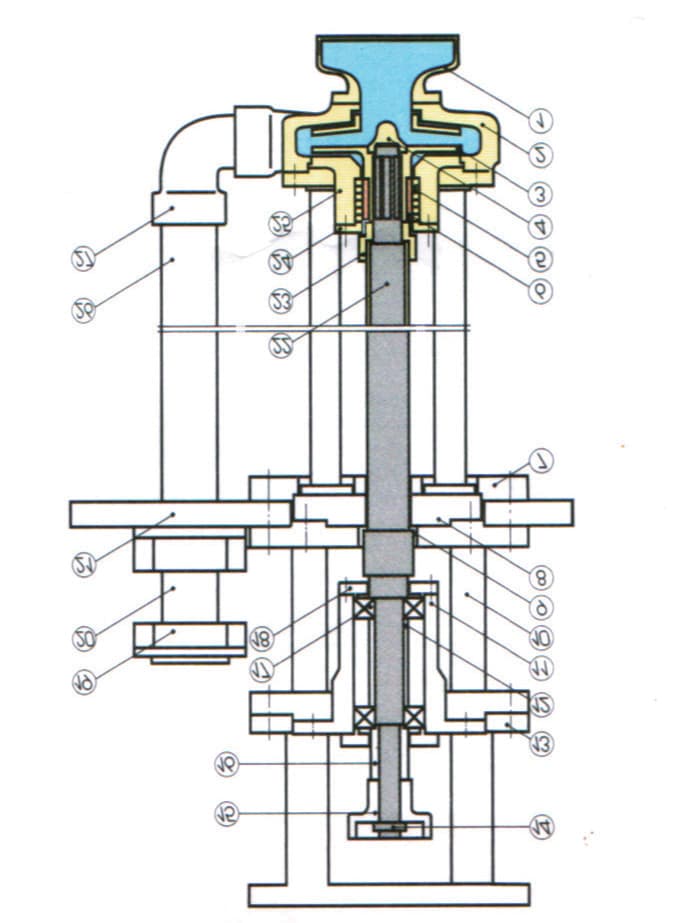

Structure and Material

1. Inlet filter 15. Pump coupler

2. Pump body 16. Coupler sleeve

3. Impeller (easily damageable) 17. Bearing (easily damageable)

4. Impeller nut 18. Bearing gland

5. Packing (easily damageable) 19. Split flange

6. Shaft sleeve (silicon nitride / easily damageable)

20. Outlet pipe

7. Supporting board 21. Base plate (seat)

8. Connecting frame assembly 22. Pump shaft

9. Steel nut 23. Fastening nut

10. Bearing support 24. Packing gland

11. Bearing box 25. Pump cover

12. Bushing 26. Discharge pipe

13. Support 27. Bend pipe

14. Round nut

Removal and Assembly

1.1 Removal

1.1.1 Remove 19. Loosen and remove 20, 26 and 27.

1.1.2 Removal all the bolts between 8 and 2.

1.1.3 Fix the coupler and make it unable to rotate. Use the accompanying spanner to remove 4 in clockwise direction as viewed from pump inlet.

1.1.4 Knock 24 slightly with a wood end wrapped with cloth. Make 3, 24 and 25 fully disengaged.

1.1.5 Replace 5 and 6.

1.2 Assemble in a sequence reverse to 1.1.

1.3 After assembly, the end face of key on pump shaft 22 shall not be

higher than impeller 25; otherwise, a gasket shall be added beneath 25.

1.4 After assembly, the impeller shall cause no friction with the pump body.

1.5 Between 3 and 4, 3 and 23, the F4 tape shall be added per the original standard, so as to prevent the liquids from entering the pump shaft.

2.1 Removal

2.1.1 Remove as described in 1.1.

2.1.2 Remove the motor and 13.

2.1.3 Remove the bolts between 10 and 11. Pull out the pump shaft.

2.1.4 Remove the steel nut and disengage 14, 15, 16 and 18.

2.1.5 Knock 11 slightly and remove it. Knock 17 with hard wood and separate it.

2.1.6 Replace 17.

2.2 Assemble in a sequence reverse to 2.1.

2.3 The bearing must be installed in pair.

2.4 After assembly, the pump shaft shall have no end play.

2.5 The sealing face shall have no damage.

Troubleshooting

|

Fault

|

Cause

|

Solution

|

|

No liquid pumped

|

1.The pump rotates in reverse direction. .

2.The impeller nut is loose.

3.The roller bearing is damaged.

|

1.Adjust the rotating direction of the pump.

2.Tighten the impeller nut.

3.Replace the roller bearing.

|

|

The head and flow are low

|

1.Impeller is damaged.

2.The motor speed is low.

3.Too many elbows on outlet pipe

|

1.Replace the impeller.

2.Increasing the rotating speed.

Arrange the pipeline properly

|

If Wo Long’s legal interest is damaged by illegal competition, Wo Long reserves all the rights to protection of its lawful interest.

We also supply:

CQB Series Fluorine Plastic Alloy Magnetic Pump FZB Series Fluorine Plastic Alloy Self-suction Pump

IMD Series Fluorine Plastic Alloy Magnetic Pump FSB (D) Series Fluorine Plastic Alloy Centrifugal Pump

ZMD Series Self-suction Magnetic Pump IHF Series Fluorine Plastic Alloy Centrifugal Pump

UHB-ZK Series Mortar Pump

Different fluorine interlined valves, sight glass, pipes and fittings

English

English

Network Supported

Network Supported